Rusting. Blistering. Cracking. Peeling. Pitting. Chalking. Delaminating.

These words may be all too familiar if you’re responsible for keeping a wastewater treatment plant up and running. Yet the harsh environment surrounding this crucial infrastructure can pack a corrosive punch. But you can proactively prevent the deterioration of wastewater pipes, tanks and buildings. A protective coating evaluation is where to start.

On a nationwide scale, corrosion is a big problem. The price tag to prevent and fix damage to concrete, metals and other materials in wastewater treatment facilities is estimated at tens of billions of dollars a year.

– Joseph Cesarek, NACE, SEH Coating Specialist

Corrosion can seriously affect your community’s infrastructure. Not only are rusted pipes and pitted concrete unsightly, but they can also cause danger to public health, damage the environment and disrupt your community’s budget. Pardon the pun, but corrosion can eat into the lifecycle of your valuable infrastructure. It can cost taxpayers money that’s better spent elsewhere. And talk about sleepless nights: corrosion can contribute to problems that cause unscheduled shutdowns and emergency repairs.

Combatting corrosion

The process of selecting, applying and maintaining protective coatings can be complex. It’s crucial to pay attention to project details such as surface preparation, coatings specifications, structural appurtenances, process coordination, industry standards and containment challenges.

But you don’t have to go it alone. Be proactive and schedule a coatings evaluation and inspection by a qualified consultant. With their help, you can design a plan to protect your wastewater assets. Proper and timely coating evaluations are a cost-effective way to extend your equipment lifecycle and maximize your budget dollars.

3 reasons why a protective coatings evaluation could benefit your community:

1. It may be time. Many of 14,500+ wastewater treatment plants in the United States built or expanded in the 1970s following passage of the Clean Water Act are nearing the end of their 50-year lifespan and may need to be updated. Mechanical equipment and conveyance equipment used for treating wastewater may have an even shorter lifespan of 20 years. SEH recommends that facilities and equipment be evaluated for corrosion about every five years to extend the overall lifespan of your infrastructure.

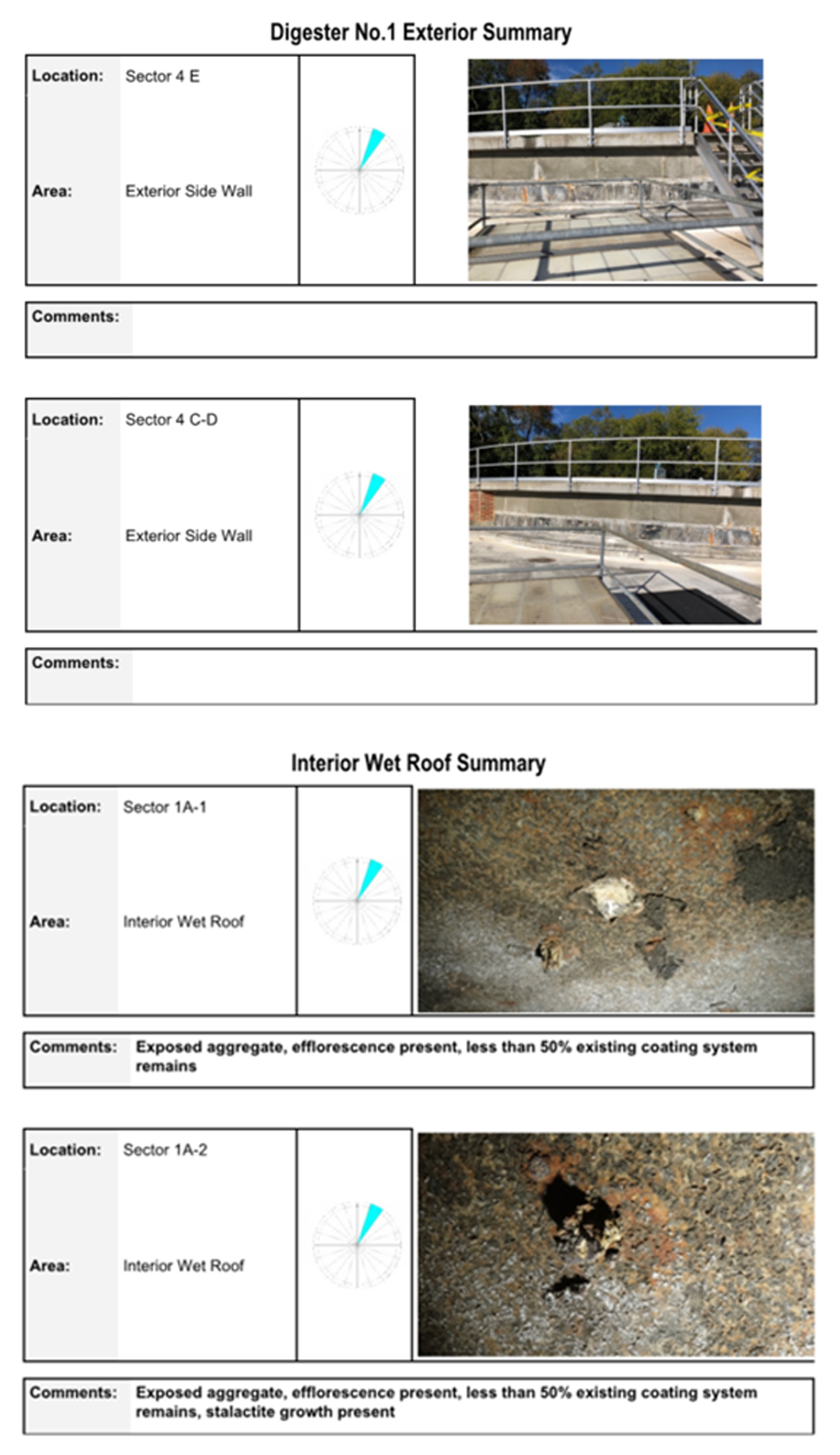

2. Avoid costly and dangerous surprises. By being proactive, you can avoid dangerous and costly leaks, spills and failures of wastewater treatment structures, equipment and conveyance systems. With a comprehensive report in hand that details the findings of a protective coating evaluation, you can prioritize repairs and schedule planned maintenance on your terms, avoiding surprise shutdowns and emergency repairs. Corrosion can cause structural failures on concrete, steel and other non-ferrous metal surfaces, resulting in an unexpected and costly shutdown. Specialized equipment such as 3D scanners can uncover some of the safety concerns in areas that are hard to reach yet you know might be there – and keeping you up at night. 3D scanning of equipment such as wet wells, mixing chambers and splitter structures is a safe, efficient and reliable way to understand the havoc that corrosion may be reaping.

Wastewater treatment infrastructure most vulnerable to corrosion:

- H2S (hydrogen sulfide gas) concentrated environments

- Primary, secondary and final clarifiers

- Flow, diversion and splitter structures

- Pipes and pipe appurtenances

- Boiler and reactor vessels

- Flue gas and odor-control systems

- Flooring and containment areas

- Structural steel framing

- Intumescent fireproofing

3. Extend the lifespan of valuable infrastructure. Your community has invested heavily in wastewater treatment, so you want to ensure that the materials that make up your facilities – think concrete, steel and mechanical parts – last as long as possible to bolster your return on investment (ROI). The harsh environment of water treatment facilities affects every exposed surface of each building, tank, pipe and machine. Some corrosion may be inevitable, but you can prevent corrosion from spreading at an accelerated rate.

Schedule a conditions assessment to evaluate existing protective coatings and determine their remaining lifespan. If any immediate repairs are necessary, perform those repairs as soon as possible. A conditions assessment can also help you plan ahead: keep track of potential challenges so you and your ratepayers can budget for long-range planned maintenance. If you prioritize one repair over another, areas of isolated but severe corrosion can be repaired before the entire structure needs total rehabilitation.

Add future maintenance costs to your community’s capital improvement plan (CIP). Maintenance planning budgeted over a multi-year schedule can save thousands of dollars compared to the cost of complete rehabilitation.

Are protective coatings preventing corrosion at your facility?

Now is the time to be proactive to maintain your wastewater treatment facility. By scheduling a protective coatings evaluation, you’ll know which parts of your system are working to combat corrosion and which ones may need attention. Use this knowledge to make informed, strategic decisions to prioritize maintenance needs. When you ensure that protective coatings are doing their job, you’ll help maximize your community’s tax dollars as well as your wastewater system’s efficiency, safety, life span and ROI.

Common steps in protective coating evaluations:

Facility and equipment evaluation

- Perform evaluations that meet the standards of ASTM and SSPC (Society for Protective Coatings), which may include:

- Dry Film Thickness (DFT) readings

- Adhesion testing (destructive testing), at the discretion of the client

- Observed degree of rusting

- Observed degree of blistering

- Ultrasonic thickness readings of pitted steel

- Review structural conditions

- Review equipment conditions

- Provide multimedia report of findings:

- Condition of concrete, steel and non-ferrous metal substrates

- Condition and expected remaining lifecycle of existing coatings

- Coating repair recommendations

- Repair cost estimates

- Repair prioritization

Project plans, specifications and design assistance

- Pre-design

- Specifications and contract documents

- Bidding administration

Third-party QC and QA inspection

Construction administration

Final review

Warranty inspection (2 years)

About SEH Protective Coatings Services

Our award-winning team has decades of experience providing solutions through protective coatings evaluations and inspections for clients across the United States. SEH is proud to be one of few consulting firms with an in-house team of SSPC-trained coating specification specialists, experienced project managers and NACE-certified field inspectors. We are honored to have been awarded numerous Sherman-Williams Impact Awards and American Council of Engineering Companies (ACEC) honor awards in protective coatings management.

SEH offers coating evaluations and inspection services tailored to meet your needs. Please contact us to schedule this service, or to learn more about how we can help extend your peace of mind by designing a plan to protect your wastewater assets.

About the authors

Eric Miller is a wastewater process engineer with experience in the planning and design of wastewater treatment facilities, including the development of coatings and tank lining specifications and review of coatings submittals. He has experience preparing facility planning documents, project specifications, operation and maintenance manuals as well as biological modeling of wastewater facilities.

Jeremiah Wendt is a professional engineer with vast experience in water and wastewater engineering. As a consultant and previous Director of Public Works, Jeremiah has designed wastewater treatment facilities, including preliminary treatment, aerated lagoons, activated sludge processes, attached growth processes, solids handling, disinfection, tertiary filtration, and collection system components such as lift stations and force main. In addition to the design process, he is experienced with report preparation, specification writing, construction inspection and wastewater treatment plant operational assistance.