Keeping drivers safe is the top priority in areas where falling rocks can cause hazardous situations for motorists. But when the only other route through the area adds more than 100 miles to your trip, timing the project to fix conditions is critical.

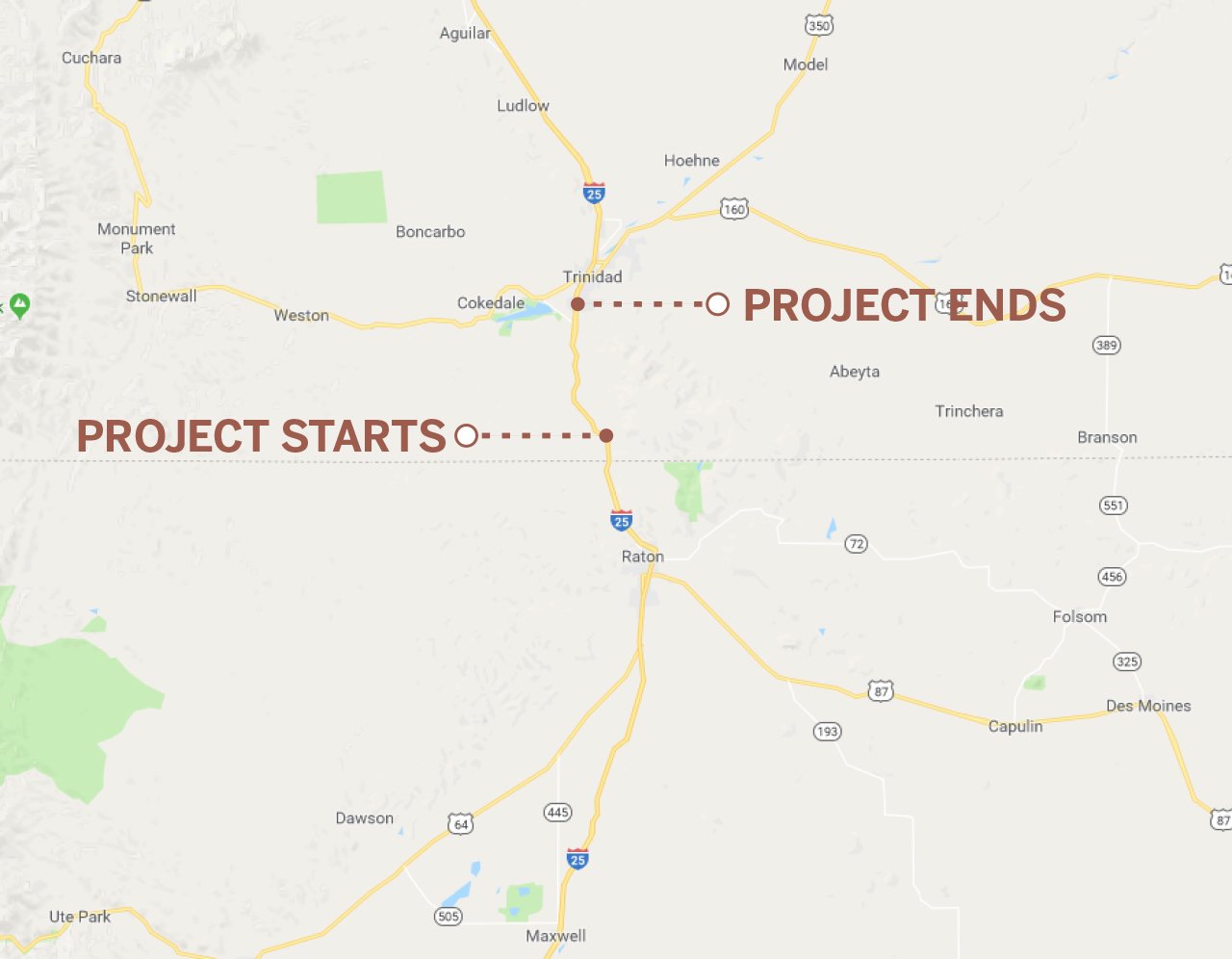

Interstate 25 (I-25) runs north and south from El Paso, Texas through Wyoming. Raton Pass, from Trinidad, Colorado to the New Mexico state line is notorious for rock falls. Large sandstone blocks sat atop weathered shale cliffs and would frequently fall on to the highway below. This created a dangerous situation for drivers and required continuous clean-up efforts by the Colorado Department of Transportation (CDOT).

Removing the blocks and securing the cliff face would be no easy task. The project team concluded they would use controlled blasting which would essentially move the mountain back from the highway. This created a 30 ft. wide ditch that prevents falling rock from reaching the highway. The shale layers were also stabilized to prevent further degradation to the cliff face.

Previous rock fall projects along Raton Pass caused long traffic delays resulting in public complaints. The team knew traffic management would be key to the success of this project.

All traffic was removed from the northbound I-25 lanes adjacent to the cliffs during construction for driver safety and to minimize traffic delays. The northbound traffic was detoured to the southbound lanes utilizing a two-lane, two-way head-to-head configuration for a length of seven miles. This configuration was in place for 12 weeks while the project was completed. This allowed the contractor to work more efficiently. The team also used a rock disposal area on the northbound side, which was closed to traffic. The contractor was also able to work on weekends and holidays. This resulted in an early completion date for the project.

We knew that scheduling and staging the project would be critical to its success.

– Tom Wrona, SEH project manager

The scheduling and adjustments

Originally, the project was scheduled to begin on March 3, 2017 with a completion date of June 29, 2017. The goal was to complete the project before the busy July 4 travel weekend. However, CDOT expressed concerns with snow removal and maintaining accident-free travel during March, historically a heavy snowfall month along the corridor.

To avoid beginning the project during March, the team delayed the start date by a month. This also pushed the project completion date to August 2017, creating another potential problem.

“We were concerned pushing the project back would result in delays to the contractors hauling out the rock material when they would be driving amongst the heavier traffic,” Wrona says.

Traffic along Raton Pass is very heavy in the summer months, often with slow moving vehicles making their way along the corridor. The rock hauling vehicles would cause further delays as they slowly made their way along the pass to a disposal site several miles away. To address the concern, the project team identified two rock disposal sites that were within the area closed to traffic. This much closer location significantly reduced both time and haul cost for the project. After, soil was placed on top of the fill and the entire area was revegetated.

In addition, when blasting the cliff faces, the team could only shut down the road for up to 20 minutes at a time. They had to ensure all blast rock was contained within the closed down northbound lanes and any errant rock that fell on the detour lanes was removed immediately.

According to Wrona, delays to the public were not the only thing the team had to keep in mind when configuring the detour. They had to develop a plan in case of emergencies.

Incident management/public information

Because there are no short, alternate routes for emergency vehicles without traveling more than 100 miles out of the way and the two-way detour had narrow shoulders with no room for passing, the team developed a solid incident management/public information plan. To craft the plan, the team met with stakeholders from local fire and police departments, sheriffs, emergency dispatch, state patrol, CDOT, the New Mexico Department of Transportation (NMDOT) and contractors.

"The stakeholder meeting was really what was key in ensuring that emergency personnel could do their jobs and the project remained on track," Wrona says.

Dispatch services needed to know the exact status of the roadway at all times to properly direct emergency vehicles to the fastest route. The team made sure one lane of the closed northbound route was opened each night, on weekends and holidays for emergency access. Because parts of the roadway would be impassable during the blasting events, the project team stayed in close contact with emergency dispatchers, notifying them when blasting events were finished and the road was cleared.

If a serious accident were to have occurred within the head-to-head detour, shutting it down for an extended period of time, the project team had another plan in place. CDOT and NMDOT coordinated the use of their variable message signs to let motorists know of a shut down and alternate routes. Fortunately, these contingent measures were not used. Lastly, the team arranged for off-duty state troopers to patrol the stretch on weekends and holidays to provide extra support should emergency services or tow vehicles need to be called in quickly to prevent back-ups and delays.

Wrapping it up

On a busy stretch of highway through Northern New Mexico and Southern Colorado, rock falls from the mountainside create dangerous conditions for drivers. As the only north/south artery through that area for more than 100 miles, the project team could not completely shut down the roadway to travel for extended periods of time. Careful scheduling involving several stakeholders from two states allowed the team to complete the project without any significant delays to motorists or sacrifices to public safety.

This project is a recipient of a Colorado Contractors Association/CDOT project management award.

About the author

Tom Wrona is a project engineer, construction manager and motorist who knows the most important step of any project is the plan.

.png?width=113&name=SEH_Logo_RGB%20(1).png)