The Environmental Protection Agency (EPA) introduced the Lead and Copper Rule (LCR) to protect the safety and quality of drinking water. This regulation required community water systems (CWS) to create inventories of lead service lines (LSLs) by the compliance deadline, which has now passed. If your system has not yet met these requirements, it is critical to act promptly to ensure compliance and protect public health.

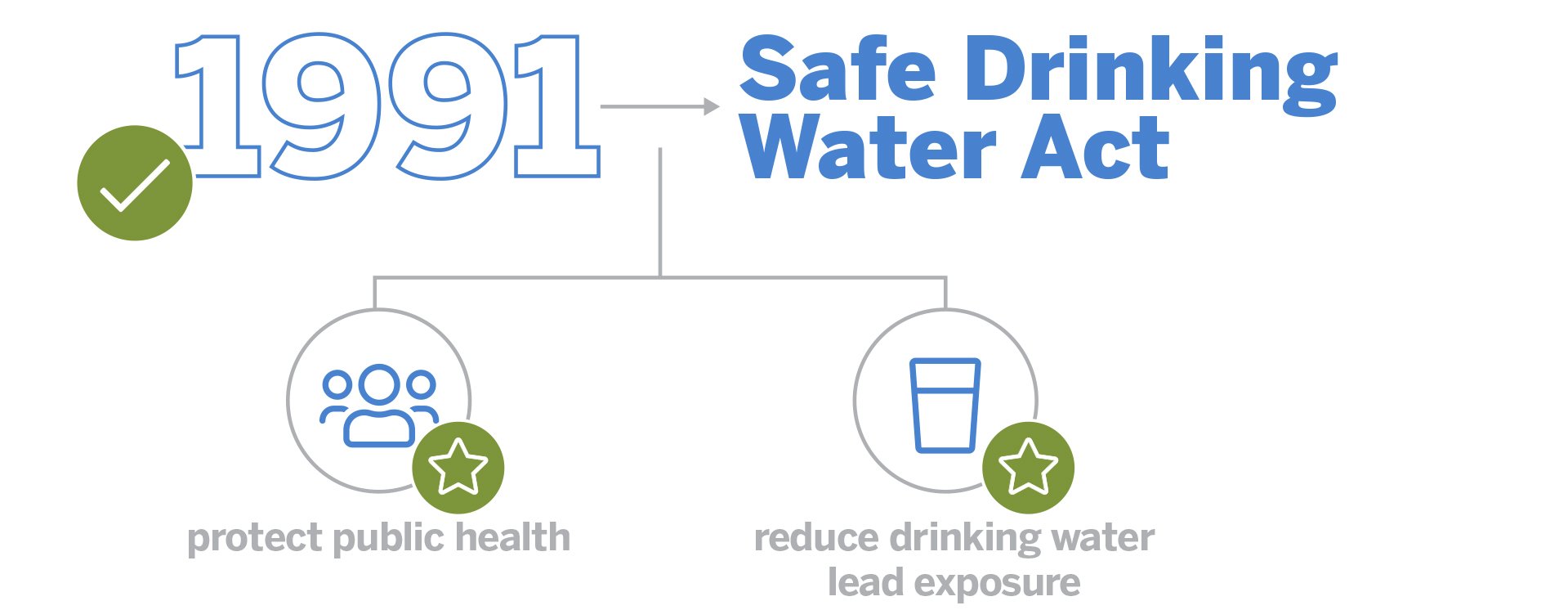

Established in 1991 as part of the Safe Drinking Water Act (SDWA), EPA’s primary objective with the LCR is to protect public health and reduce exposure to lead in drinking water.

So, what do you need to know, and what steps do you need to take to protect your community from lead exposure and meet the EPAs goal of complete lead service line removal? This article provides essential details, highlights available funding resources, and outlines the steps to follow to help ensure the safety of your residents by eliminating all lead service lines and providing clean and healthy drinking water for all.

Timeline of EPA Lead and Copper Rules:

States may have stricter drinking water regulations than the EPA. Check your state for more information.

Lead service line inventory requirements

The LCRR specifies requirements of the initial inventory to include:

Material classification. Each service line, including portions with split ownership, must be classified as lead, galvanized requiring replacement (GRR), non-lead, or lead status unknown.

All service lines and ownership. The inventory shall include both the system- and customer-owned portions of all service lines within the distribution system.

Information to identify material. Service line materials shall be classified using previous materials evaluations, construction and plumbing codes/records, water system records, distribution system inspections and records, information obtained through normal operations, and state-specified information.

Initial inventory submission and updates. Submit your initial inventory to the appropriate regulatory agencies to comply with the Lead and Copper Rule requirements. Water systems that demonstrated the absence of LSLs by the stated October 16, 2024, deadline are not required to provide an update. However, if these systems subsequently find any LSL or GRR service line, they have 30 days to notify the state and prepare an updated inventory on a schedule established by the state. Afterward, inventories must be updated and submitted to primacy agencies annually or triennially, depending on lead tap sampling frequency, but not more frequently than annually.

Public accessibility. Inventories shall be made publicly available and include a locational identifier for LSLs and GRR service lines. Water systems serving more than 50,000 people must provide inventories online.

Consumer confidence report (CWSs only). CWSs must inform the public how to access the service line inventory information through their consumer confidence report.

Service line consumer notification. Notification must be provided to individuals served by the water system at the service connection with an LSL, GRR, or lead status unknown service line. For water systems serving communities with many non-English speaking consumers, as determined by the state, public education materials must be in appropriate languages or contain a telephone number or address where they may contact the water system to obtain a translated copy of the materials or to request assistance.

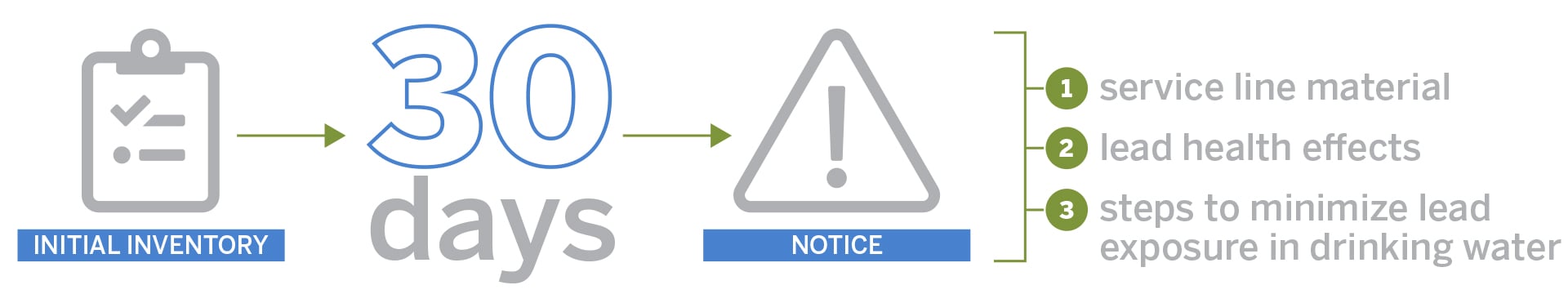

Notification must be provided within 30 days after completion of initial inventory and repeated annually until only non-lead lines remain. Water systems must also provide this notice for new customers during service initiation. Notice must include a statement about service line material, lead health effects, and steps to minimize lead exposure in drinking water. If the service line is:

- Confirmed LSL: notification must include opportunities to replace the LSL, any available financing programs, and a statement that says the system must replace its portion if property owners notify the system that they are replacing their portion.

- GRR: notification must also include opportunities for service line replacement.

- Lead status unknown: notification must also include opportunities to verify the material of the service line.

Notification delivery must be by mail or by another method approved by the state. The water system will need to report that the notification was delivered and provide a copy of the notification and information materials to their states annually by July 1 for the previous calendar year.

Building and creating your lead service line inventory

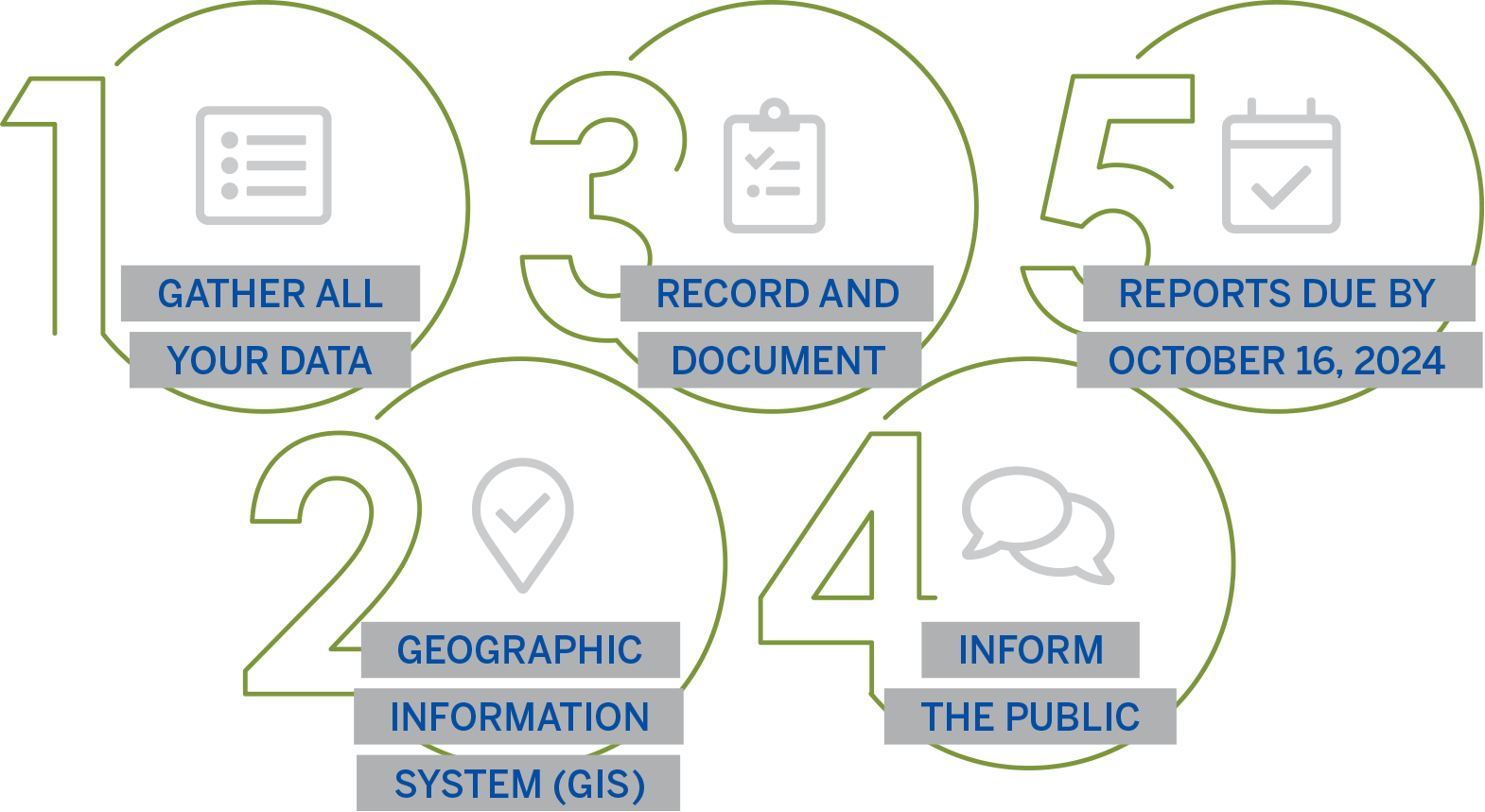

Building an LCRR-required service line inventory is a systematic process that SEH can simplify for you. Below are five steps to build and create your inventory.

1. Gather all your data

- Include both utility and privately owned sides of the service line.

- Collect existing records, maps, and documentation related to the water distribution system, such as as-built drawings, maintenance cards, engineering reports, and construction records.

- Review historical records to determine the age of the water distribution system and any significant upgrades or replacements conducted over the years.

- Conduct field surveys to visually identify service line material and document the types of pipes visible, such as those visible where the water service enters the home or inside meter pits. Document service line materials during maintenance activities such as meter replacements.

- Collaborate with property owners by conducting surveys, questionnaires, or interviews to gather information about their service lines including age, material, and location.

2. Geographic Information System (GIS)

- If available, use GIS to map and track the locations of service lines.

- Incorporate data from water billing records, field surveys, property owner information, and existing records into the GIS system to create a comprehensive inventory.

3. Record and document

- Create a detailed inventory database or spreadsheet to record all the relevant information about each service line, including location, material, age, and other pertinent data.

- Ensure the information is organized and easily accessible for future reference.

- Regularly update the service line inventory with new information or when changes occur in the water distribution system.

- Implement a maintenance plan to periodically review and validate the inventory.

- Analyze the inventory data to assess the extent of LSLs and prioritize areas for replacement.

4. Inform the public

- Explain the LSL inventory mandate to your community and provide information on its significance.

- Meet with residents to provide information, evaluate situations, and acquire required documentation.

5. Submit inventory report

- Prepare reports or summaries outlining the findings of the service line inventory, including the number and percentage of LSLs and their classification – lead, galvanized requiring replacement, non-lead, or lead status unknown.

- If your system does not have LSLs, compile proof with an inventory of non-lead materials or a written statement of verification.

- Submit the reports to the appropriate regulatory agencies and provide customers with information about their service line material.

- Provide necessary customer notifications notifying them of their service line material.

Funding and tools for lead service replacements

Removing LSLs from drinking water systems can be costly for communities or water utilities. Funding options are available at the federal and state levels. Here are some sources to consider.

Federal funding

- Community Development Block Grants (CDBG) are administered through the U.S. Department of Housing and Urban Development (HUD)

- Water Infrastructure Improvements for the Nation (WIIN) includes grant funding for reducing lead in drinking water in disadvantaged communities under the Reducing Lead in Drinking Water Grant Program.

- Water Infrastructure Finance and Innovation Act (WIFIA) Program provides long-term, low-cost supplemental loans for regional and nationally significant projects.

- U.S. Department of Agriculture (USDA) Rural Development Water and Waste Disposal Loan and Grant Program provides rural communities with populations under 10,000 financing support.

State funding

- Drinking Water State Revolving Fund (DWSRF), established by the EPA, has provided states with funding since it originated. The DWRF offers below-market rate loans for public water system improvements and is a common funding source for drinking water projects.

- New programs like the EPA’s Lead Service Line Replacement Accelerators and the Get the Lead Out Initiative provide technical assistance, guidance, and additional resources to streamline project implementation and funding applications.

SEH has supported countless communities in the process of applying for, securing, and administering funds through the DWRF program. Learn more about our funding services and connect with a funding expert.

Additional tools

- EPA’s document, Guidance for Developing and Maintaining a Service Line Inventory, can be used to comply with the requirements under the LCRR that are in effect at the time of document publication, August 2022.

- The LSLR Collaborative released a new toolkit for utilities, public health officials, and local leaders to tackle lead pipes in their communities. The online toolkit includes a roadmap for getting started; suggested practices to identify and remove lead service lines in a safe, equitable and cost-effective manner; policies that federal and state leaders could adopt to support local efforts; and links to additional resources that may be helpful when developing local programs.

- EPA's very useful publication for answering questions regarding other funding sources available for various types of projects, Funding and Technical Resources for Lead Service Line Replacement in Small and Disadvantaged Communities.

About the Experts

Kevin Young, PE (MN, VA), has experience in different positions directly related to water treatment. He has served as a water treatment plant operator, engineer, and supervisor at a 10 mgd lime softening facility. His operations experience includes ozone disinfection, biological filtration, chlorination, and high service pumping. He is passionate about the environment and our responsibility to provide clean water to everyone.

Simon McCormack, PE (MN), has in-depth knowledge of water system engineering from design to operation. He is well-informed about the SDWA, Minnesota Plumbing Code, Minnesota Well Code, and procedures for enforcing these standards. In addition to engineering design and operation, Simon is well-versed in hydraulic modeling and integrating modeling software with GIS systems.

.png?width=113&name=SEH_Logo_RGB%20(1).png)